Once upon a time, bullbar fabricators would build the biggest strongest barwork they could to reduce damage from the likes of animal strikes and minor collisions. Traditional truck bullbar designs used horizontal and vertical members intersecting at right angles, essentially looking like a cattle grid. Things are changing though!

While the primary purpose of protecting the vehicle from damage remains, a truck bullbar must now be compatible with modern and new systems including airbags and frontal under-run protection (FUP). Not to mention motor vehicle safety systems like crumple zones in the unfortunate event of a truck vs car incident. The bars also need to be aesthetically pleasing, complimenting the design and shape of the truck.

A visit to the Irvin Bullbar manufacturing facility in Midvale will show a dedicated team of designers and fabricators making everything from a simple nudge bar to a big robust truck bar, some of the best barwork in the business. Irvin Bullbars has been supplying bars as dealer-fitted accessories, panel beater replacements and to the ever-growing number of retail customers since 1976 when Irvin’s opened in Esperance in the Great Southern.

Since the move to Midvale in 1982, the business has steadily evolved into the thriving hub it is today, with 23 people on the payroll and looking to expand that number. The staff are long term employees, with the foreman being employed for over 30 years, most of the fabricators between 10-15 years and the main polishers the same.

Here in the West, truck operators love to tweak the design of their bullbar to personalise their vehicles. We welcome customer feedback on any of the barwork we make, it helps us learn from their ideas and assists us find better ways to do things. Obviously, we need to keep in mind the Australian Driving Regulations as well as local Department of Transport rules, so some customisation just can’t happen. FUP compatible bullbars are a matter of following the guidelines and not upsetting any of the safety features already on the truck, things like adaptive cruise control radars.

Sourcing the best materials is paramount to a strong truck bar. This and the Irvin Bullbar design ensure you have the best possible protection on your rig. High quality product is standard and is what sets Irvin Bullbars apart. Extruded channel sections set the foundation of any truck bar, a platform that maximises the strength. High tensile, marine grade sheet is used for extra strength and RHS and tubes are the heaviest wall thickness in the industry.

The bars can be finished in a chrome like polished finish or a heavy duty powdercoated appearance. The beauty of the powdercoating is your fuel tanks and or steps can be powdercoated too for easy maintenance.

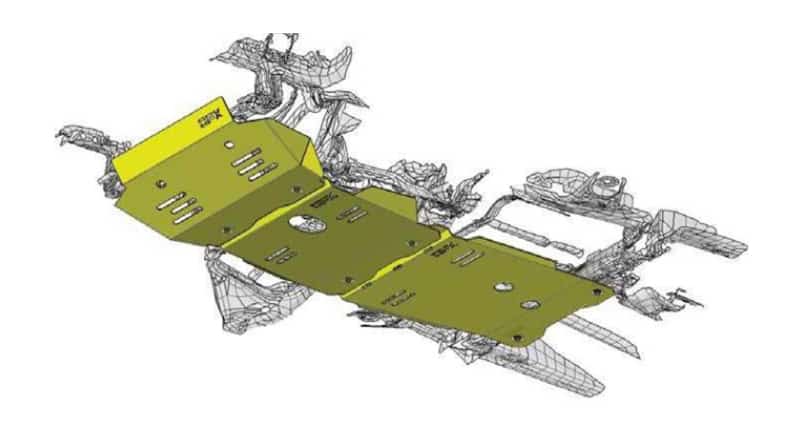

The subframe/tilt mechanism is one of the most important parts of the truck bar, connecting the bullbar to the truck chassis and maximising the performance of the bullbar. Using specially designed jigs and templates as well as some components being CNC cut ensures strength and reliability, your truck bar will be protecting your motoring investment for years to come.

The team at Irvin Bullbars are turning out bespoke barwork that serve the dual purpose of enhancing the vehicles looks yet providing protection and safety.

It’s worthwhile to pop in to speak to one of the bullbar experts and get your truck bar into the system.

For more information on our bulbar protection solutions, be sure to download our ‘Bullbar Information Pack’ today.